Company News

What Crusher to Choose for Quartz Stone Crushing?

28/12/2025

Quartz stone is a mineral raw material with high hardness and strong wear resistance. Selecting the right crusher is crucial for improving production efficiency, reducing energy consumption, and ensuring product particle size. Below are common types of crushers for quartz stone crushing and selection recommendations.

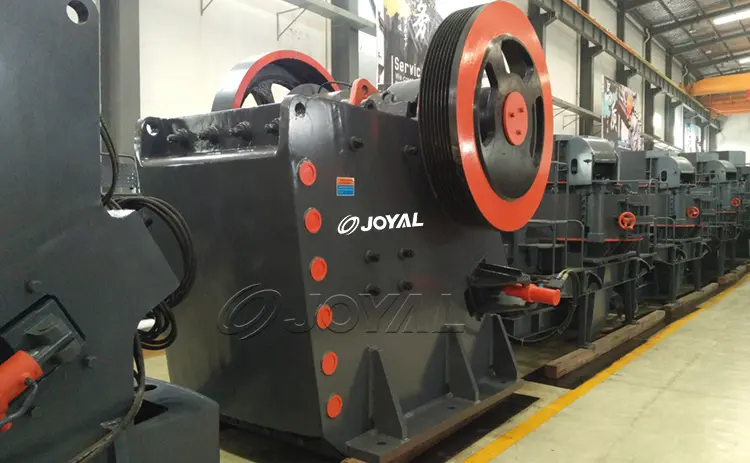

1. Jaw Crusher (Primary Crushing)

- Application Stage: Primary Crushing (Coarse Crushing)

- Characteristics:

- Large crushing ratio, capable of handling large quartz stones (feed size up to 1200mm).

- Simple structure, easy maintenance, and strong impact resistance.

- Suitable for the initial crushing of high-hardness materials.

- Recommended Model: PEV series deep-cavity jaw crushers are better suited for hard rock crushing.

2. Cone Crusher (Secondary/Fine Crushing)

- Application Stage: Secondary Crushing (Intermediate or Fine Crushing)

- Characteristics:

- Utilizes the laminated crushing principle, ideal for high-strength, high-hardness quartz.

- Long service life of wear parts, stable operation, suitable for continuous production.

- Adjustable discharge size (typically 5-60mm).

- Type Selection:

- Single-cylinder Hydraulic Cone Crusher: High automation, suitable for medium/fine crushing.

- Multi-cylinder Hydraulic Cone Crusher: Higher crushing efficiency and better product shape.

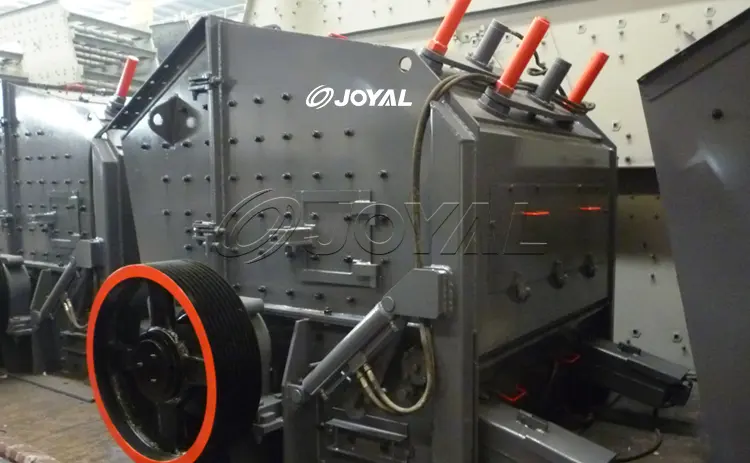

3. Impact Crusher (Vertical Shaft Impact Crusher – Sand Making Stage)

- Application Stage: Tertiary Crushing (Sand Making or Shaping)

- Characteristics:

- Ideal for producing 0-5mm manufactured sand with rounded grain shape and good gradation.

- The “rock-on-rock” or “rock-on-iron” principle reduces wear part consumption.

- Combines crushing and shaping functions, increasing the added value of quartz sand.

- Note: For quartz with very high silica content and extreme hardness, opt for wear-resistant configurations (e.g., ceramic alloy impact blocks).

4. Double Roll Crusher (Optional for Fine Crushing)

- Application Stage: Fine crushing of medium-hard materials, or scenarios sensitive to over-crushing.

- Characteristics:

- Gentle crushing process, less dust generation, uniform product size (2-10mm).

- Suitable for small-to-medium scale production or where flaky particles are acceptable.

- Limitation: Rapid wear of roller skins when processing high-hardness quartz, requiring frequent replacement.

5. Hammer Crusher (Use with Caution)

- Suitability: Generally not recommended for quartz stone.

- Reasons:

- The high hardness of quartz (Mohs hardness 7) accelerates hammer head wear.

- Prone to generating dust, and product size control is difficult.

- Exception: May be used only for small-scale crushing of lower-hardness quartzite.

Typical Configuration for a Quartz Stone Crushing Plant

- Primary Crushing: Jaw Crusher (product size ≤200mm).

- Secondary Crushing: Cone Crusher (product size ≤40mm).

- Tertiary Crushing/Sand Making:

- If manufactured sand is needed: Vertical Shaft Impact Crusher (product size 0-5mm).

- If only fine particles are needed: Multi-cylinder Cone Crusher or Double Roll Crusher (product size 5-20mm).

- Auxiliary Equipment:

- Vibrating Feeder (for even feeding)

- Vibrating Screen (for grading and screening)

- Belt Conveyor

- Dust Collection System (Quartz dust is hazardous to health; enclosed dust removal is essential.)

Key Factors for Crusher Selection

- Raw Material Properties: Feed size, hardness (SiO₂ content >90%), moisture content.

- Capacity Requirements: Hourly output (e.g., 50 t/h, 200 t/h).

- Finished Product Requirements: Particle size distribution, grain shape (cubic or angular), powder content.

- Investment & Operational Costs:

- Cone crushers have a higher initial investment but lower long-term operating costs.

- Impact crushers are suitable for high value-added sand-making stages.

- Environmental Requirements: Fully enclosed process with dust collection to prevent silicosis risk.

Summary & Recommendations

- For Large-scale Plants (Hard Quartzite):

Jaw Crusher + Cone Crusher + Impact Crusher (if sand making is required) - For Small/Medium Scale, Emphasizing Grain Shape:

Jaw Crusher + High-efficiency Fine Jaw Crusher/Cone Crusher + Double Roll Crusher - Focus on Sand Making:

Fine Crushing Cone Crusher + Impact Crusher (in “rock-on-rock” mode)

It is recommended to conduct ore crushing tests before final selection and consult with equipment manufacturers (such as shanghai JOYAL) for customized solutions. Also, pay attention to the selection of wear-resistant materials for the equipment (e.g., high manganese steel, ceramic composites) to handle the highly abrasive nature of quartz stone.