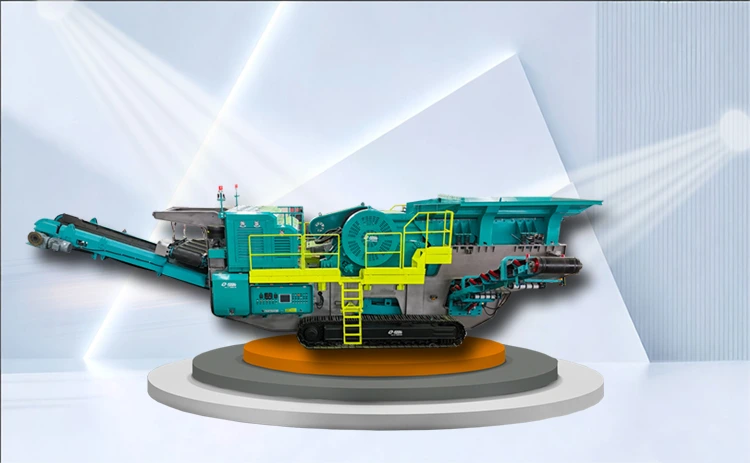

The mobile crushing station is an efficient and portable equipment in the mining and stone processing industry. It consists of several key modules, each playing a critical role throughout the processing operation. This article provides a detailed introduction to the main structural components of the mobile crushing station produced by JOYAL and explains the function of each module.

Feeder

The feeder is the initial module of the mobile crushing station, primarily responsible for supplying raw stone materials to the next processing stage. It controls the feed rate according to production requirements and ensures a uniform supply of materials. The stability and reliability of the feeder directly affect the efficiency of subsequent crushing and screening operations.

Crusher

The crusher is the core module of the mobile crushing station. Depending on production needs, it can be configured with different types such as jaw crushers, impact crushers, or cone crushers. After the stone materials are delivered by the feeder, they enter the crusher’s chamber, where internal forces compress and break them down. The crusher reduces large stones into smaller fragments of the desired size, ensuring a smooth progression to the next processing stages.

Vibrating Screen

The vibrating screen plays a vital role in the screening process within the mobile crushing station. After being crushed, the stones are sent to the vibrating screen, where they are classified according to different particle size requirements. This ensures that sand and stone products that meet specifications are obtained, improving the overall processing yield.

Conveyor

The conveyor serves as the connecting module in the mobile crushing station, responsible for smoothly transporting crushed and screened materials to the next processing stage. It can adjust transport speed and angle as needed, ensuring continuous material flow. The conveyor links all the modules together, contributing to the efficient operation of the entire system.

In addition to the core modules mentioned above, the mobile crushing station also includes auxiliary equipment such as power control cabinets, lubrication systems, and control systems. The power control cabinet supplies electricity to the entire setup and manages the operation of various motorized components. The lubrication system is essential for the proper functioning of mechanical parts, providing lubrication and maintenance to extend equipment lifespan. The control system acts as the brain of the mobile crushing station, monitoring and controlling the operational status of each module while enabling intelligent adjustments and optimization.

As an efficient and portable solution for mining and stone processing, the structural design of the mobile crushing station determines its stability and productivity during operation. Each module performs an indispensable function, working in coordination to ensure high efficiency throughout the entire process. With continuous technological advancements, the design and performance of JOYAL’s mobile crushing stations will keep improving, delivering greater convenience and benefits to the mining and stone processing industry.