Company News

Crusher Selection for Iron Ore

17/12/2025

Shanghai Joyal engineers remind:Iron ore is hard and abrasive. Choosing the right crusher depends on the ore properties, production scale, and final product requirements. A multi-stage crushing process is typically used.

1. Recommended Equipment by Stage

Primary Crushing (Large lumps → 100-300mm)

- Jaw Crusher: Most common, robust, handles large feed well.

- Gyratory Crusher: For large-scale mines, very high capacity.

Secondary Crushing (~300mm → 30-100mm)

- Cone Crusher (Top Choice): Wear-resistant, energy-efficient, ideal for hard ore.

- Hydraulic Cone Crushers are recommended for automation and protection features.

- Impact Crusher: Good product shape, but less wear-resistant. Suitable only for medium/low hardness ore.

Tertiary/Fine Crushing (Product ≤ 10-30mm)

- Cone Crusher (Short-head or multi-cylinder type).

- High-Pressure Grinding Rolls (HPGR): Energy-saving and efficient, ideal for modern, large plants.

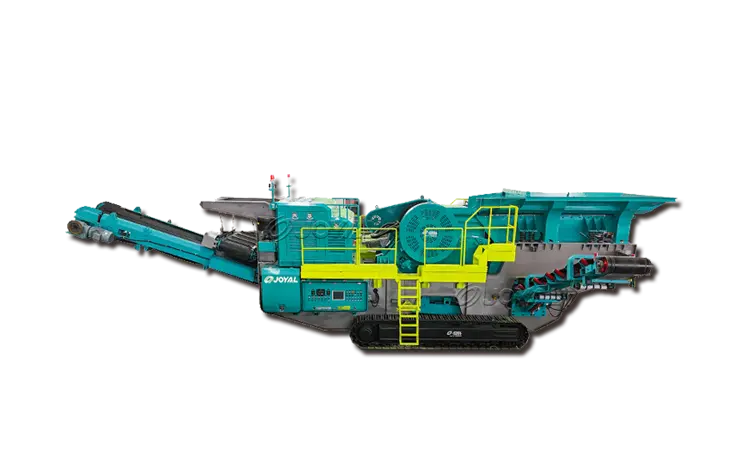

Mobile Crushing Plant

- Flexible and convenient for medium/small or scattered mining sites.

2. Key Selection Guidelines

- For Hard Ore (e.g., hematite, magnetite): Prioritize cone crushers.

- Medium/Small Scale: Jaw crusher (primary) + cone crusher(s) (secondary/tertiary).

- Large Scale: Gyratory crusher (primary) is an option; HPGR can be added for fine crushing.

- Wear Parts: Use high-manganese steel or other wear-resistant materials.

- Auxiliary Equipment: Always include a feeder and magnetic separator/ metal detector.

3. Common Process Flows

- Two-Stage & Closed-Circuit:

ROM Ore → Jaw Crusher (Primary) → Cone Crusher (Secondary) → Screening (oversize returns to crusher). - Three-Stage & Closed-Circuit:

ROM Ore → Gyratory/Jaw Crusher (Primary) → Cone Crusher (Secondary) → Cone Crusher/HPGR (Tertiary) → Screening in closed circuit.