Company News

Considerations in Marble Crushing Plant Design

20/12/2025

1. Material Characteristics

- Hardness Variation: Mohs hardness 3-5, design for hardest conditions

- Moisture Impact: Up to 8-12% in wet seasons, require anti-clogging design

- Dust Generation: High CaCO₃ content (>95%) requires enhanced dust collection

2. Process Design Essentials

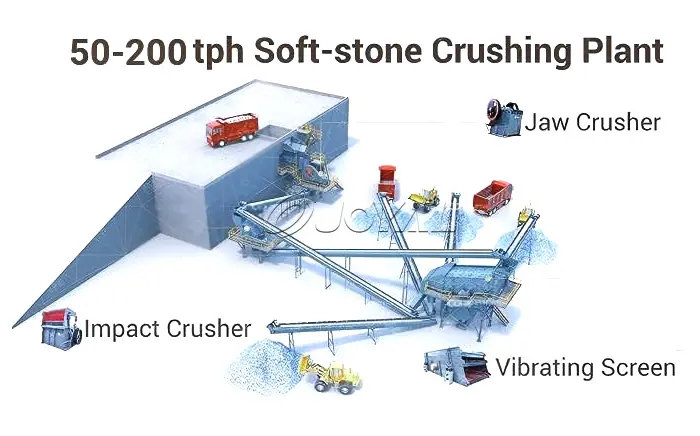

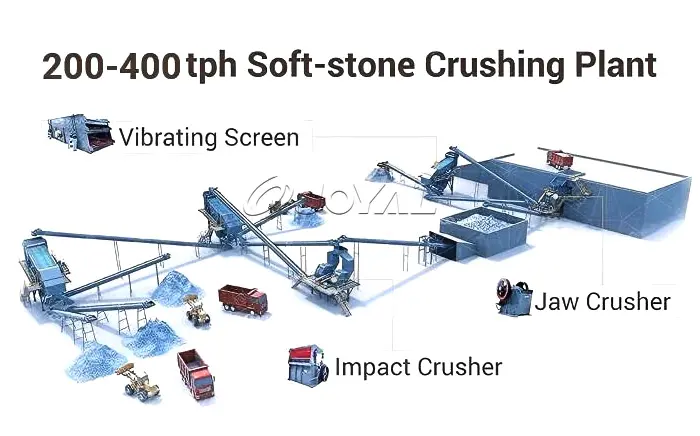

Crushing Stages Selection

Two-Stage: -30% capex | Poor particle shape (>15% flaky) Three-Stage: Standard | Good shape (<8% flaky) Four-Stage: Premium | Cubic shape (<5% flaky)

Flexibility: Allow space for future tertiary crusher addition

Key Equipment

- Primary: Deep-cavity jaw crusher (1:8 reduction ratio)

- Secondary/Finishing: Impact crusher for better shape, cone crusher for lower wear cost

- Critical: Crusher speed control (38-42 m/s optimal)

Screening System

- Screen Type: Polyurethane decks last 3-5× longer despite 40% higher initial cost

- Anti-Blinding: Essential due to marble dust adhesion

- Efficiency: Multi-deck screens achieve 85-92%

3. Quality Control Points

- Particle Shape: Target <10% flaky for premium aggregate

- Fines Control: 10-15% in manufactured sand (MB value <1.4)

- Dust Emission: Bag filter efficiency >99.5%, emission <20 mg/m³

4. Environmental & Safety

Dust Control System

Three-Level Approach: 1. Source: Enclosure + high-pressure spray (>4MPa) 2. Process: Covered conveyors + extraction points 3. Treatment: Bag filters + 15m stack

Noise Management

- Equipment enclosures: -15 to -20dB

- Boundary standards: Day <65dB, Night <55dB

Water Management

- 95% water recycling rate

- Sludge dewatering >60% solids

5. Automation & Energy Saving

- Control Levels: PLC + optional MES/cloud platform

- Key Monitoring: Crusher current/temperature/vibration, energy consumption

- Energy Optimization: VFDs on feeders/conveyors (-15 to 25%), IE3+ motors (+3-5% efficiency)

6. Maintenance & Accessibility

- Clearance: 1.5× equipment width around crushers

- Lifting: Dedicated hoists for each major machine

- Wear Parts: Liner change target <8 hours

7. Investment & Operations

Phased Implementation

Phase 1 (Years 1-2): 60% investment - Base capacity Phase 2 (Years 3-4): 25% investment - Shaping/sand making Phase 3 (Year 5+): 15% investment - Value-added products

Operational Targets

- Power: 1.0-1.3 kWh/ton

- Wear Parts: $0.7-1.1/ton

- Labor: 3-4 operators per shift (300tph)

8. Common Design Pitfalls

- Over-Crushing: Excessive fines increase energy 30-50%

- Undersized Screening: Causes >150% circulating load

- Conveyor Bottlenecks: Restricts overall capacity

- Dust System Undersizing: Actual airflow = 1.2-1.5× theoretical

9. Design Checklist

- Complete material test reports

- Reasonable crushing stage ratios (Primary 1:6-8, Secondary 1:4-6)

- Circulating load 100-120%

- Backup for critical units (feeders/screens)

- Meets local environmental standards

- Adequate maintenance access

- Remote diagnostics capability

- Energy monitoring system