Company News

Which type of crusher should be chosen for crushing gold ore?

06/01/2026

1. Common Crusher Types for Gold Ore

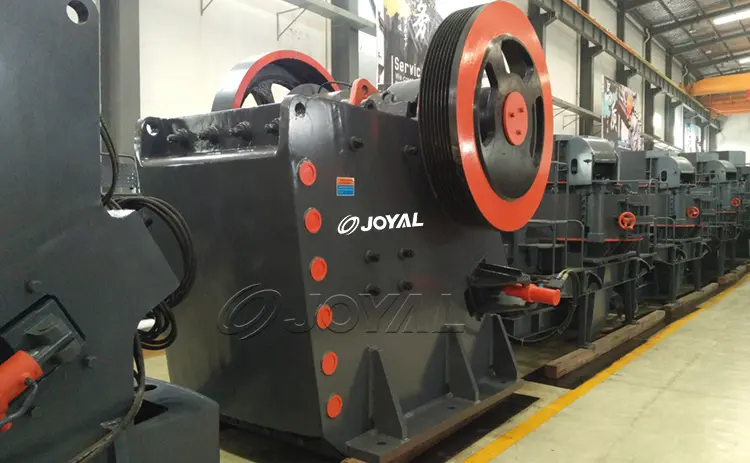

- Jaw Crusher

- Stage: Primary Crushing

- Best For: Large, hard ore (compressive strength ≤320MPa).

- Key Points: Simple, robust, high capacity. Produces coarse output (typically 10-350mm). Works best with low-clay ore.

- Cone Crusher

- Stage: Secondary/Tertiary Crushing

- Best For: Medium to hard ore (e.g., quartz vein gold).

- Key Points: High efficiency, low energy consumption, produces uniform product with minimal overgrinding. Hydraulic models allow easy adjustment.

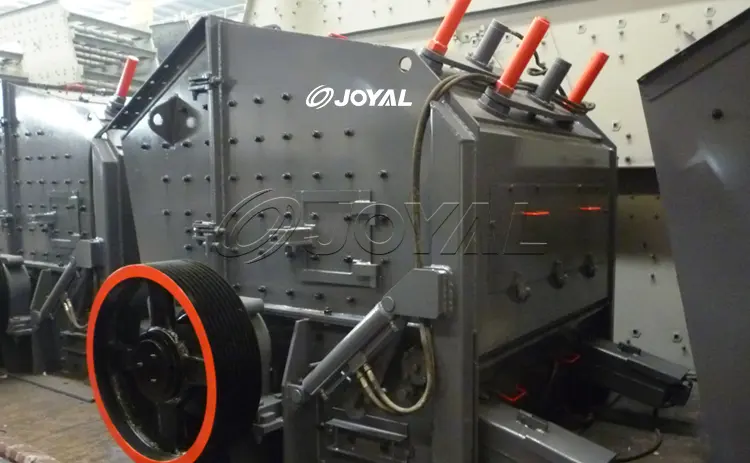

- Impact Crusher (Vertical Shaft Impactor – VSI)

- Stage: Tertiary Crushing / Sand Making

- Best For: Medium hardness, brittle ore.

- Key Points: High reduction ratio, good grain shape. Supports “more crushing, less grinding” for energy savings. Prone to clogging with high-clay ore.

- High-Pressure Grinding Rolls (HPGR)

- Stage: Fine/Ultra-fine Crushing

- Best For: Medium-hard ore with fine-grained gold.

- Key Points: Highly energy-efficient, promotes early mineral liberation, significantly reduces grinding load. Higher initial investment, suitable for large-scale operations.

- Hammer Crusher

- Stage: Secondary/Tertiary Crushing

- Best For: Soft, brittle ore (e.g., oxidized ore).

- Key Points: High reduction ratio and capacity. Rapid wear with hard ore and prone to clogging with clay.

2. Key Selection Factors

- Ore Properties: Hard ore → Jaw + Cone crusher combo. High clay content → Consider pre-washing or clog-resistant designs.

- Product Size: Target >100mm after primary → Jaw crusher. Target <10mm for grinding → Cone crusher or HPGR.

- Capacity: Small plant (<500 t/d) → Jaw + Hammer/Impact crusher. Large plant (>2000 t/d) → Jaw + Cone + HPGR.

- Process Flow: Traditional: Three-stage closed circuit (Jaw + Cone + Screen). Energy-saving: Jaw + HPGR (replaces multiple stages).

3. Example Flowsheets

- Hard Quartz Vein Gold Ore:

Primary: Jaw Crusher (<150mm)

Secondary: Cone Crusher (<50mm)

Tertiary: Cone Crusher or HPGR (<10mm)

Closed-circuit with vibrating screens. - Soft Oxidized Ore (High Clay):

Primary: Jaw Crusher (with grizzly for clay removal)

Secondary: Impact or Hammer Crusher (<8mm)

Wet screening may be necessary.

4. Important Considerations

- Wear: Quartz is highly abrasive. Use wear-resistant materials (e.g., manganese steel liners).

- Clogging: For clayey ore, include washing or pre-screening.

- Automation: For large plants, automated control systems optimize performance.

Recommendation Summary

- Small Operations: Jaw + Hammer/Impact crusher for low cost and easy maintenance.

- Large Operations: Jaw + Cone + HPGR for maximum efficiency and energy savings (“more crushing, less grinding”).

- Fine-Grained Ore: Prioritize HPGR for early liberation.