Analysis of Core Advantages and Technical Value of Mobile Crushing Stations

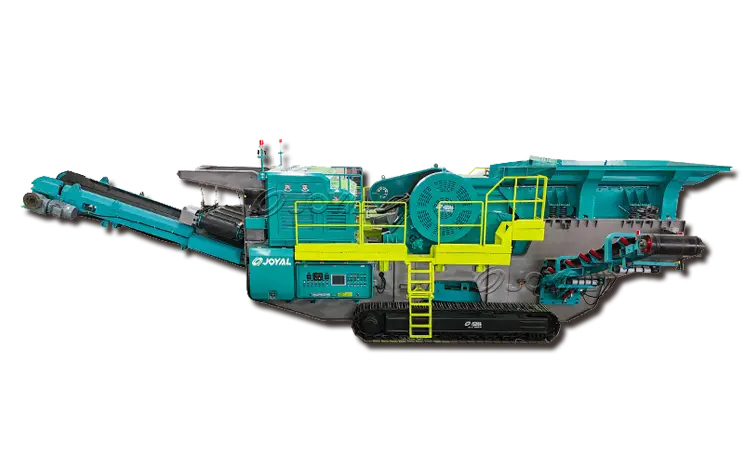

Mobile crushing stations, also known as mobile crushers or mobile crushing plants, are highly integrated rock crushing equipment that combine feeding, crushing, screening, and conveying into a single unit. Their core design philosophy is “on-site crushing,” offering revolutionary advantages over traditional fixed production lines across multiple dimensions.

I. Overview of Core Advantages

The core advantages of mobile crushing stations can be summarized as “Three Highs and One Low”: High Mobility, High Flexibility, High Cost-Effectiveness, and Low Environmental Impact.

II. Detailed Analysis of Technical Advantages

1. Unparalleled Mobility and Relocation Efficiency

- Rapid Deployment: The equipment is mounted on its own chassis (tracked or wheeled), can be towed by truck or self-propelled, and can be operational within 30 minutes of arriving on-site, requiring no foundation piling or fixation.

- Proximity to Material Source: Can be driven directly to mining sites, construction waste piles, or project sites, embodying “crush where the material is,” significantly reducing material transport distance and costs.

- Continuous Multi-Site Operation: Ideal for projects with short timelines and dispersed work sites (e.g., road construction, urban demolition/renovation), allowing quick relocation between different sites for extremely high utilization rates.

2. Significant Economic Benefits

- Reduced Transport Costs: On-site processing eliminates the need for long-distance hauling of raw feed and finished aggregate, representing the largest area of cost savings.

- Lower Infrastructure Investment: Eliminates the need for concrete foundations and steel support structures, saving time and material costs.

- Flexible Rental Models: Project-based companies can opt for rental arrangements, avoiding large capital expenditures and optimizing cash flow.

- Labor and Energy Savings: Highly automated controls reduce on-site operating personnel; streamlined processes also lower overall energy consumption.

3. Superior Process Flexibility and Configuration Versatility

- Modular Design: Can be flexibly configured with modules like jaw crushers, cone crushers, impact crushers, and screens based on raw material properties (hardness, size), product requirements (gradation, size), and site conditions, forming “crushing then screening” or “screening then crushing” flows.

- Multiple Drive Options: Choice of diesel drive (for remote sites with no external power), electric drive (environmentally friendly and quiet, for sites with grid access), or hybrid power.

- Easy Product Adjustment: Final product specifications can be quickly changed by adjusting crusher settings, changing screen meshes, or altering screen angles.

4. Strong Environmental Adaptability and Social Benefits

- Reduced Dust and Noise: Modern models are equipped with comprehensive spray dust suppression systems and soundproofing designs. Some models allow fully enclosed operation, better complying with urban environmental regulations.

- Construction Waste Recycling: Serves as key equipment for on-site crushing and resource recovery of urban construction and demolition (C&D) waste, supporting the circular economy and “zero-waste city” initiatives.

- Excellent Terrain Adaptability: Tracked mobile plants offer superior performance on rough, muddy, or sloped terrain, minimizing site preparation requirements.

- Improved Community Relations: Reduces the number of heavy truck trips on public roads, alleviating traffic congestion and community disturbances.

5. Intelligent Control and Ease of Operation & Maintenance

- Centralized Electrical Control: All equipment is controlled from a single console or even via remote control/mobile app monitoring, enabling one-touch start/stop and fault diagnosis.

- Convenient Maintenance: Key components are easily accessible, with maintenance points designed for ergonomics. Features like hydraulic supports and quick-open devices on some models reduce maintenance time.

III. Comparison with Traditional Fixed Production Lines

| Feature | Mobile Crushing Station | Fixed Crushing Plant |

|---|---|---|

| Installation & Relocation | Virtually no installation needed; rapid relocation. | Requires complex foundation construction; permanent, extremely difficult to relocate. |

| Investment Cost | Relatively lower initial investment; lower operational costs (esp. transport). | High initial infrastructure investment, though unit equipment cost may be lower. |

| Application Scenario | Projects with short cycles, dispersed sites, or unconcentrated material sources. | Long-term (10+ years), stable extraction at very large-scale quarries/mines. |

| Environmental & Community Impact | Enables on-site processing, reducing transport impact. | Typically requires centralized processing, leading to significant material transport impacts. |

| Flexibility | Very high, can be reconfigured as needed per project. | Very low, plant configuration is fixed. |

IV. Typical Application Scenarios

- Urban Construction, Demolition, and Renovation Waste Recycling

- On-site Aggregate Supply for Linear Projects like highways, railways, and bridges

- Crushing in Medium/Small Quarries, Granite, and River Gravel Operations

- Resource Utilization of Mine Tailings and Metallurgical Slag

- Rapid Clearance and Processing of Disaster Zone Debris