Non-Metallic Ore

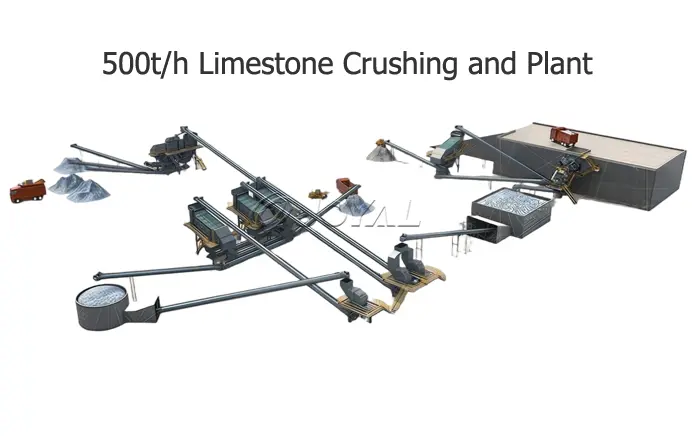

500t/h Limestone Crushing and Sand Making Plant

10/12/2025

I. Design Basis

- Raw Material: Limestone, feed size ≤750mm.

- Products: 0-5mm manufactured sand (~200 t/h); 5-10mm, 10-20mm, and 20-31.5mm high-quality aggregates (~300 t/h).

- Capacity: ≥500 tonnes per hour (stable operation).

- Process: Three-stage crushing (primary, secondary, tertiary) + Vertical Shaft Impact (VSI) sand-making. Dry process. Centralized dust collection.

II. Process Flow & Equipment Configuration

[Raw Material] → [Feeding & Screening] → Jaw Crusher → [Soil Removal Screen] → Cone Crusher → [Pre-Screen] →

[Cone Crusher] (Tertiary, closed circuit) → [VSI Crusher] → [Final Screen] → [Air Classifier] → [Product Silos]

↑

[Aggregate Bypass]

Core Equipment List:

| Stage | Equipment | Key Function |

|---|---|---|

| 1. Primary Crushing | Vibrating Feeder (ZSW1860) | Uniform feeding & pre-screening. |

| Jaw Crusher (PE1200×1500) | Reduces large feed to ≤300mm. | |

| 2. Secondary/Tertiary Crushing | Cone Crushers (HPT300 / HPT500) | Closed-circuit crushing for high-quality aggregates. |

| Circular Vibrating Screen (3YKD3070) | Pre-screening; separates finished aggregates & oversize for recirculation. | |

| 3. Sand Making | VSI Crushers (VSI6X1263 ×2) | Core sand-making and shaping units. High sand yield. |

| 4. Screening & Grading | Multi-deck Vibrating Screens (4YKD3680 ×2) | Final product screening and precise sizing. |

| Air Classifier (Optional) | Adjusts fines content in manufactured sand; improves quality. | |

| 5. Auxiliary | Pulse-jet Dust Collection System (Centralized) | Comprehensive dust control for environmental compliance. |

| Belt Conveyor System | Material handling and transfer. | |

| PLC Central Control System | Automated process control and monitoring. |

IV. Key Features

- High Efficiency & Reliability: The combination of a robust jaw crusher and closed-circuit cone crushers ensures continuous, high-volume production.

- Superior Product Quality: Cone crushers produce well-shaped aggregates. VSI crushers deliver manufactured sand with excellent gradation and particle shape.

- Smart & Eco-Friendly: Full-line PLC control with key monitoring points. Enclosed design at major dust generation points with high-efficiency dust collectors.

- Operational Flexibility: Product mix and specifications can be adjusted within a range by modifying screen meshes, crusher settings, and classifier operation.