I. Design Principles

Tailored for basalt’s high hardness and abrasiveness, ensuring equipment durability, process stability, and production of high-quality cubical aggregates.

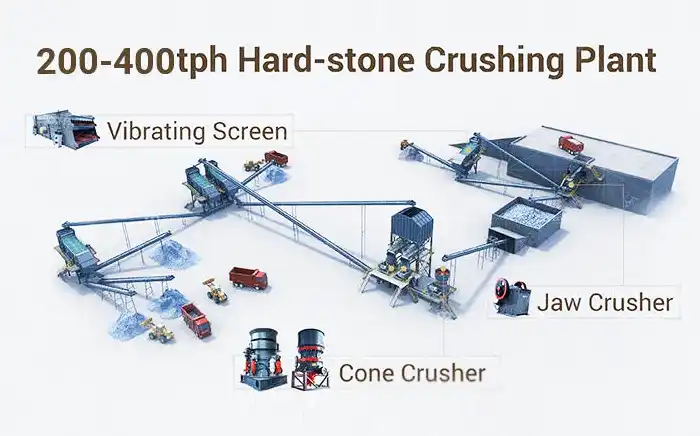

II. Process Flow

Three-Stage Closed-Circuit Crushing System (Recommended Scheme)

Raw Material Bin → Vibrating Feeder (Pre-screening) → Jaw Crusher (Primary) → Cone Crusher I (Secondary) → Cone Crusher II (Tertiary) → Screening System → Product Bins

↑_________________Recycling Conveyor System_____________________↑

III. Equipment Configuration (300TPH Baseline)

| Process Stage | Equipment | Model/Specification | Qty | Power (kW) | Output Size |

|---|---|---|---|---|---|

| Feeding | Heavy-Duty Vibrating Feeder | ZSW600×1300 | 1 | 30 | <500mm |

| Primary Crushing | Jaw Crusher | C160/CJ615 class | 1 | 250 | <250mm |

| Secondary Crushing | Hydraulic Cone Crusher | HP400/CH440 class | 2 | 2×250 | <60mm |

| Tertiary Crushing | Short-Head Cone Crusher | HP300/CH430 class | 2 | 2×200 | <30mm |

| Screening | Triple-Deck Vibrating Screen | 2.4×6.0m | 3 | 3×22 | Grading |

| Conveying | Belt Conveyors | B800-B1200 | 15-18 lines | As required | – |

| Dust Control | Pulse Bag Filter | Centralized System | 1 set | 75 | – |

IV. Product Specifications (Adjustable)

Manufactured Sand: 0-5mm Small

Aggregate: 5-15mm

Medium Aggregate: 15-25mm

Large Aggregate: 25-40mm

V. Key Design Points

- Wear Resistance: High manganese steel liners for all crushing chambers; maintain critical spare parts inventory.

- Dust Control: Fully enclosed conveying + centralized bag filter system; dust emission <20mg/m³.

- Automation: PLC central control system monitoring current, temperature, and vibration.

- Maintenance Design: Service platforms and lifting facilities for liner replacement within 8 hours.

- Layout Requirements: Equipment spacing ≥1.5× equipment width with clear maintenance access.

VI. Main Technical Parameters

- Processing Capacity: 200-400TPH (adjustable)

- Total Installed Power: ≈1800kW

- Required Area: ≈8000-12000㎡

- Operating Staff: 3-5 persons/shift

- Equipment Utilization Rate: ≥85%

VII. Project Execution

- Design Period: 4-6 weeks

- Manufacturing & Installation: 4-5 months

- Commissioning: 2-3 weeks

- Investment Scale: Medium-sized quarry equipment configuration

Scheme Features: Simplified flow, easy maintenance, excellent product shape, suitable for highly abrasive basalt conditions. Recommended to equip with a condition monitoring system for optimized wear parts replacement planning.

BASALT CRUSHERS

If you would like to inquire about pricing or learn more about our options, please leave a message below and we will reply to you as soon as possible.