- Designed Capacity: 150 tonnes per hour (rated), with 20% equipment capacity buffer.

- Raw Material: Granite, compressive strength >150 MPa, feed size ≤650mm.

- Final Products: 0-5mm Manufactured Sand, 5-10mm, 10-20mm, 16-31.5mm graded aggregates.

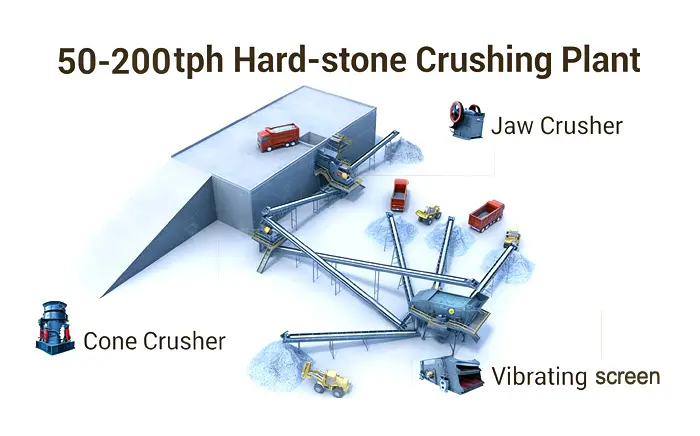

- Core Process: Three-Stage Crushing with Closed-Circuit + Independent Sand-Making & Shaping Circuit to ensure optimal particle shape and gradation.

Professional Process Flow Description

Raw Material Hopper (≤650mm) → [Heavy-Duty Vibrating Feeder ZSW-1500×5000] → [Jaw Crusher PE-1200×1500] (Primary Crushing) → [Pre-Screening for Soil Removal] →

↓

[Intermediate Hopper] → [Multi-Cylinder Hydraulic Cone Crusher HPT300 (Standard Cavity)] (Secondary Crushing) → [Vibrating Screen 3YK-3070] (Check Screening)

↓

[Vibrating Screen] → Finished Aggregates (10-31.5mm) → [Finished Product Silos]

→ Oversize/Return Material (5-31.5mm) → [Multi-Cylinder Hydraulic Cone Crusher HPT300 (Short Head Cavity)] (Tertiary Crushing) → [Vibrating Screen] (Closed Circuit)

→ Sand-making Feed (0-5mm) → [Sand-making Buffer Bin] → [Vertical Shaft Impact Crusher VSI-1140] (Sand Making & Shaping) → [Vibrating Screen 2YK-2470]

↓

Finished Sand (0-5mm) → [Finished Sand Silo]

Coarse Particles (>5mm) → [Return to VSI or direct to product]

Process Deep-Dive:

Primary Crushing & Scalping: The jaw crusher performs initial size reduction. Integrated pre-screening then removes soil and fines, boosting downstream efficiency and product cleanliness.

Secondary/Tertiary Closed-Circuit Crushing: A single, liner-switchable multi-cylinder cone crusher (Standard/Short Head) operates in closed circuit. This ensures ≤30mm feed to the sand circuit, maximizing sand yield and controlling particle shape.

Independent Sand-Making Circuit: A dedicated buffer and screen form a flexible semi-closed circuit. It allows switching between “Rock-on-Rock” (for shape/wear) and “Rock-on-Iron” (for yield/fines) modes, enabling precise control of sand’s fineness modulus and powder content.

III. Core Equipment List & Technical Specifications

| Stage | Equipment Name | Recommended Model / Technical Specs | Key Selection Rationale & Configuration Points |

|---|---|---|---|

| Feeding & Scalping | Heavy-Duty Vibrating Feeder | ZSW-1500×5000 (with Grizzly Section) | Capacity ≥400 tph. Grizzly bars at the front remove soil, protecting primary crusher. |

| Primary Crushing | Jaw Crusher | PE-1200×1500 (with hydraulic adjustment) | Heavy-duty cast steel moving jaw, high-inertia flywheel design. Hydraulic toggle plate overload protection is more reliable than traditional mechanical types. |

| Secondary/Tertiary Crushing (Core) | Multi-Cylinder Hydraulic Cone Crusher | HPT300 (compatible with dual cavity liners) | Heart of the plant. Employs laminating crushing principle for superior cubical product. Fully hydraulic adjustment and cavity clearing for high automation. Equip with constant-temperature lubricating oil system for bearing longevity. |

| Screening & Grading | Circular Vibrating Screen | 3YK-3070 (Check Screen), 2YK-2470 (Product Screen) | Screen box uses combination of ring groove rivets and high-strength bolts to prevent cracking. Externally mounted bearing housing for easy maintenance. Polyurethane/Rubber composite screen panels reduce noise and prevent blinding. |

| Sand Making & Shaping | Vertical Shaft Impact Crusher | VSI-1140 (Central Feed with Cascade) | Recommended: Four-port tungsten carbide tipped wear parts for balanced life. Hydraulic lid opening for easy maintenance. Optional on-line particle shape analyzer for feedback control. |

| Conveying System | Belt Conveyors | B800-B1200 (for main lines) | Line all transfer chutes with wear-resistant ceramic or UHMW liners. Install a Suspended Magnet (after primary) and a Metal Detector (before cone crusher). |

| Dust Control | Pulse Jet Baghouse Dust Collector | LPM-360 (Centralized System) | Use membrane-coated anti-static filter bags. Total air volume ≥36,000 m³/h. Key control points: Crusher in/outlets, screen enclosures, all transfer points. |

| Control & Automation | Centralized Control System | PLC + Industrial HMI + SCADA Software | Must include: Sequential start/stop, real-time monitoring & alarm for key parameters (current, temperature, vibration), automatic production tonnage tally, and pre-alarm for critical bearing temperatures. |

IV. Professional Operational & Cost Considerations

- Wear Parts Strategy: The largest variable cost for a granite plant.

- Cone Crusher Liners: Use constant wear curve designed mantle/concaves to extend life by 15-25%.

- VSI Wear Parts: Opt for high-chromium cast iron with tungsten carbide inserts for optimal cost-to-life ratio.

- Screen Media: Use rubber screen panels on top decks for anti-blinding and noise reduction; polyurethane panels on bottom decks for precise sizing.

- Capacity Adjustment:

- Increase to ~200 tph: Requires paralleling an identical cone crusher in the tertiary stage. Space and interfaces must be预留 (pre-designed).

- Decrease to ~50 tph: Reduce feeder rate, switch cone crusher to tertiary (short head) cavity, and run in single-circuit mode.

- Key Performance Indicators (KPIs):

- Specific Power Consumption: ≤ 2.5 kWh / tonne of product

- Specific Wear Parts Cost: ≤ 1.0 RMB / tonne of product

- Overall Equipment Effectiveness (OEE): ≥ 85%

- Flakiness Index of Finished Aggregates: ≤ 10%