Key points in iron ore crushing line design include: thorough analysis of ore characteristics (hardness, abrasiveness) and precise selection of multi-stage crushing equipment (jaw crusher for primary, cone crusher for secondary/fine crushing).

Crushing and processing technology of iron ore

JOYAL Mining, as an integrated supplier of complete ore crushing solutions and equipment, has rich experience in iron ore crushing and has achieved technological upgrades for many large-scale iron ore projects, effectively improving ore grade and increasing economic profits.

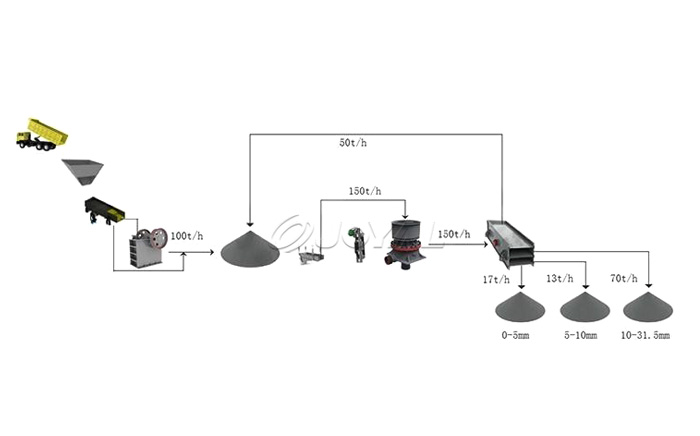

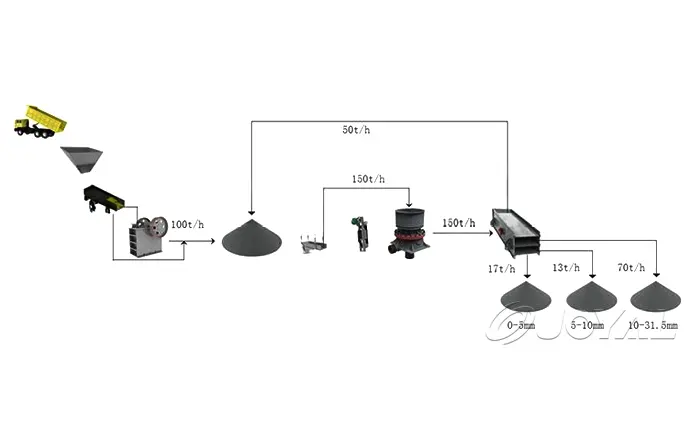

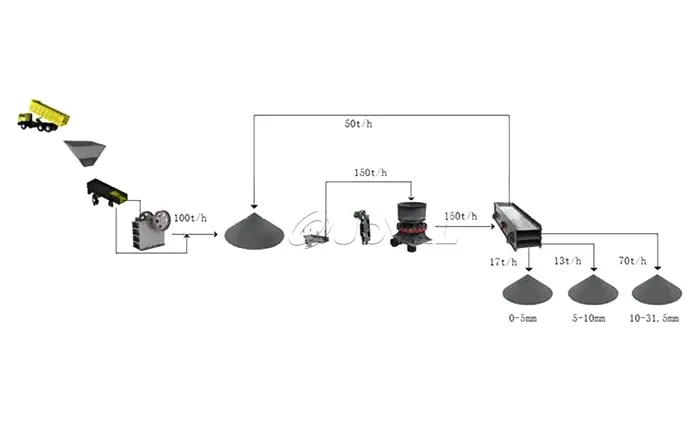

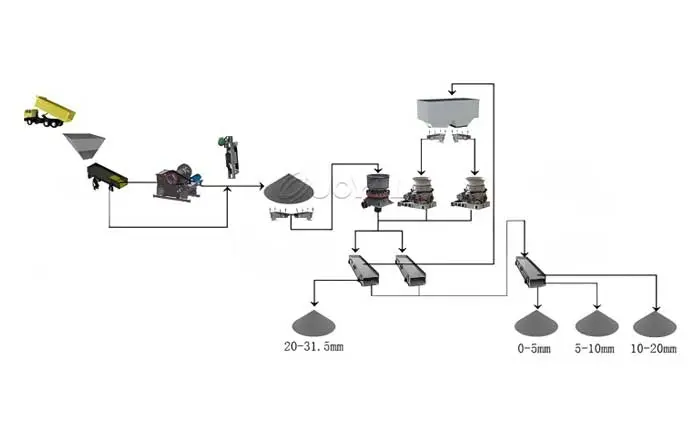

Process Flow

High-Level Storage Silo → Vibrating Feeder → Jaw Crusher (Primary Crushing) → Iron Remover → Cone Crushers*3 (Secondary & Fine Crushing) → Vibrating Screen → Finished Product (Oversize material returns to cone crushers)

Iron Ore Crushing Plant

| Equipment | Quantity | Main Function |

|---|---|---|

| High-Level Storage Silo | 1 Unit | Raw material storage & buffering |

| Raw Material Bin | 1 Unit | Temporary storage for processing |

| Vibrating Feeder | 5 Units | Uniform feeding & flow control |

| Jaw Crusher | 1 Unit | Primary coarse crushing (≤350mm) |

| Cone Crusher | 3 Units | Secondary & fine crushing (≤40mm) |

| Vibrating Screen | 1 Unit | Particle size classification & screening |

| Iron Remover / Magnetic Separator | 1 Unit | Removal of ferrous impurities |

Key Control Parameters

- Processing Capacity: 350-400 t/h

- Feed Size: ≤800 mm

- Final Product Size: 0-40 mm (Adjustable)

- Crushing Ratio: Approx. 1:20

Operational Key Points

- Vibrating feeders regulate crusher load.

- Iron remover protects downstream equipment.

- Vibrating screen enables closed-circuit circulation to ensure product size.

- Parallel cone crushers enhance system stability and reliability.

Main equipment pictures

Plan Features: Simple process, well-matched equipment, closed-circuit design, easy maintenance, suitable for iron ore hardness characteristics.