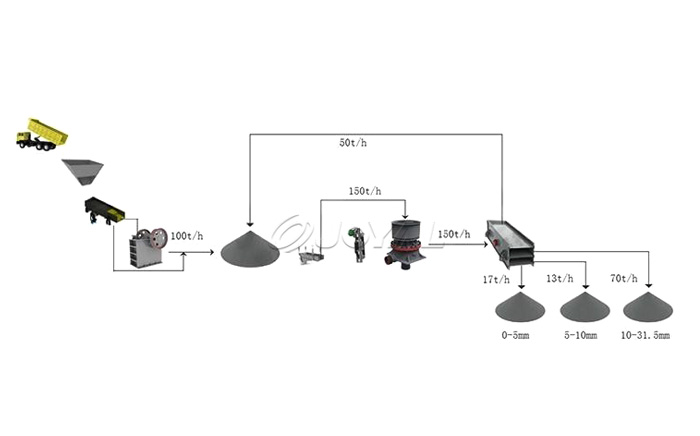

Based on the provided equipment configuration, this project is a professionally designed 100-150 t/h Gold Ore Crushing Production Line. The process begins with raw ore feeding and iron removal, followed by a two-stage crushing circuit consisting of a jaw crusher for primary reduction and a cone crusher for secondary crushing. The system incorporates a closed-circuit design with a vibrating screen to ensure precise final product size control. This efficient and reliable layout is engineered to deliver consistent throughput of crushed gold ore for downstream processing.

Core Mission: Prevent the loss of gold-bearing material at all stages to ensure maximum metal recovery. Key Measures: Enhance equipment wear resistance and sealing comprehensively to eliminate dust spillage, and optimize particle size to reduce downstream costs.

Gold ore crushing into production line configuration

| No. | Equipment Name | Model / Specification (Example) | Qty. | Key Function & Notes |

|---|---|---|---|---|

| 1 | Raw Material Bin | Capacity: 50-70 m³, with Grizzly Feeder | 1 | Initial storage & controlled feeding. |

| 2 | Apron Feeder / Vibrating Grizzly Feeder | Width: 1200-1500 mm | 1 | Uniform feeding to primary crusher, pre-screening fines. |

| 3 | Magnetic Separator (Suspended Type) | Belt width: 800-1000 mm | 1 | Removes tramp iron to protect crushers. |

| 4 | Jaw Crusher (Primary) | Feed opening: ~750×1060 mm, Capacity: ~150-200 t/h | 1 | Coarse crushing to ~150-200 mm. |

| 5 | Vibrating Feeder | Capacity: 150-200 t/h | 2 | Ensures steady material flow to secondary crusher and screen. |

| 6 | Cone Crusher (Secondary) | Cavity type: Standard/Medium, Capacity: 100-180 t/h | 1 | Medium/fine crushing in closed circuit. |

| 7 | Vibrating Screen (Closed Circuit) | Deck: 2-3, Size: 2400×6000 mm | 1 | Separates final product; returns oversize to cone crusher. |

| 8 | Belt Conveyors | Width: 800-1000 mm, Variable lengths | Set | Connects all process stages. |

| 9 | Dust Collection System | Baghouse type, Air volume: 20,000-30,000 m³/h | 1 | Controls dust at transfer points & crushers. |

| 10 | Control Panel / PLC System | Centralized control with motor monitoring | 1 | Automates operation & protects equipment. |

| 11 | Steel Structure & Platforms | Custom design for all equipment | Set | Supports equipment & provides safe access. |

| 12 | Cable & Power Distribution | Match total installed power (~350-450 kW) | Lot | Supplies power to entire line. |

Raw Material Bin → Magnetic Separator → Vibrating Feeder (1) → Jaw Crusher (Primary Crushing) → Vibrating Feeder (2) → Cone Crusher (Secondary Crushing) → Vibrating Screen (Screening) ↑ ↓ (Oversized Particles) Finished Product (To Next Process Stage)

In response to the issues of high hardness and difficulty in crushing of gold ore raw materials, as well as the higher requirements for equipment capacity and stability in gold mining production lines, Joyal Mining has developed multi cylinder hydraulic cone crushers and mobile crushing stations, which have been repeatedly demonstrated and practiced by customers. These devices have perfectly replaced imported equipment, with higher cost-effectiveness and timely after-sales service, and are highly trusted by investors in major mining areas.

If you would like to know about our equipment or production line customization, please leave us a message and we will contact you soon.