River pebbles are hard (Mohs hardness 7-8), highly wear-resistant, and have a high silica content, making them ideal raw materials for producing high-quality manufactured sand and high-grade concrete aggregates. However, this also places extremely high demands on the wear resistance of crushing equipment. The core design principle is “more crushing, less grinding,” selecting highly wear-resistant equipment, and optimizing the gradation.

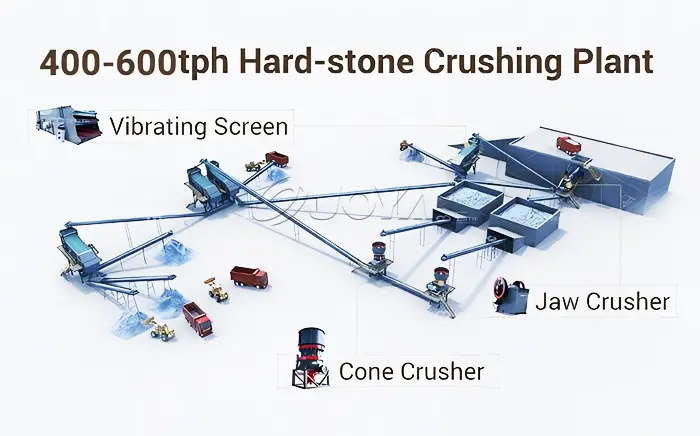

Project Overview

Raw Material: River Pebble (High Hardness, High Silica Content)

Capacity: 400-600 Tons Per Hour

Core Challenge: High Abrasion & Wear

Design Principle: “Crush More, Grind Less,” select wear-resistant equipment, optimize product particle shape.

The classic crushing process—”coarse crushing (jaw crusher) → medium crushing closed-circuit (cone crusher + screening) → fine crushing/sand shaping (cone crusher + impact crusher) → graded storage”—is specifically designed for high-hardness, highly abrasive river pebbles. Its core objectives are:

- Stable production capacity of 400-600 tph

- Production of high-quality aggregates and manufactured sand with excellent particle shape and reasonable gradation

- Control of needle-like and flaky particle content through closed-circuit circulation and shaping processes

- Full environmental protection coverage, achieving green production.

RIVER STONE CRUSHERS

Process Flow: Three-Stage & Closed-Circuit Crushing + Independent Sand Making

- Feeding & Pre-Screening

- A heavy-duty vibrating feeder with grizzly bars removes soil and natural sand smaller than 40mm from the raw feed. This reduces load on the primary crusher and improves efficiency.

- Primary Crushing

- Equipment: Jaw Crusher (1 unit)

- Function: Reduces raw material (≤750mm) to ≤200mm. Provides a stable, coarse feed for downstream processes. Simple structure offers economical wear-part costs.

- Secondary Crushing & Closed-Circuit Screening (Core Section)

- Equipment: Hydraulic Cone Crushers (2 units, in parallel) + Multi-Deck Circular Vibrating Screens (2-3 units)

- Process: Material from the jaw crusher is fed to the cone crushers. The crushed output is then screened. Oversized material returns to the cone crushers, forming a closed circuit. This ensures precise control over intermediate product size (typically ≤31.5mm) and optimal particle shape for aggregate.

- Tertiary Crushing & Sand Making/Shaping

- Tertiary Crushing: A fine-cavity cone crusher (1 unit) processes mid-sized aggregate to produce smaller, premium stone chips.

- Sand Making: Vertical Shaft Impact (VSI) Crushers/Sand Makers (1-2 units) specialize in shaping 5-15mm material to produce high-quality manufactured sand (0-5mm) with excellent grain shape.

- Environmental Protection & Control System

- Dust Control: Fully enclosed conveyors. Dust hoods at all transfer points are connected to a central pulse-jet baghouse dust collector.

- Control: A PLC-based central control system enables one-touch start/stop, process monitoring, and fault alarms for stable and efficient operation.

Main Equipment Configuration

| Process Stage | Equipment | Key Spec Suggestions | Qty | Primary Function |

|---|---|---|---|---|

| Feeding & Pre-Screen | Heavy Duty Grizzly Feeder | Grizzly Opening 40mm | 1 | Uniform feeding, removal of fines & impurities |

| Primary Crushing | Jaw Crusher | Feed Opening ≥1200x1500mm | 1 | Primary size reduction to ≤200mm |

| Secondary Crushing | Hydraulic Cone Crusher | Medium Cavity, High Wear-Resistance | 2 | Core crushing stage, forms closed circuit |

| Tertiary/Sand Making | Vertical Shaft Impact Crusher | Central/Waterfall Feed | 1-2 | Manufactured sand production & aggregate shaping |

| Screening | Multi-Deck Circular Vibrating Screen | 3 Decks, Area ≥20㎡ | 2-3 | Sizing and closed-circuit check screening |

| Dust Collection | Pulse-Jet Baghouse Dust Collector | Air volume sized per layout | 1 Set | Plant-wide dust collection |

Final Product Specification

- High-Quality Aggregate: Sized fractions such as 5-10mm, 10-20mm, 16-31.5mm.

- Premium Manufactured Sand: 0-5mm, with well-shaped particles and good gradation.

- (Optional) By-product: Naturally occurring sand and soil from pre-screening.

Key Considerations

- Wear Resistance is Paramount: Core crushing equipment (Cone & VSI Crushers) must feature high-wear-resistant configurations and components from reputable brands.

- Capacity Buffer: Equipment selection should include a 10%-15% capacity buffer to account for the high hardness of river pebble and ensure sustained target output.

- Essential Pre-Work: Conduct thorough raw material testing and analysis. Obtain detailed proposals and quotations from several specialized manufacturers before finalizing decisions.

This proposal represents a reliable, cost-effective, and competitive classic configuration for large-scale river pebble processing.